One Row Drilling Machine with Horizontal and Vertical Positions / Woodworking Machinery / Boring Machine / Power Tools

TQS-MZ1A 1 Row Boring Machine One boring row with two standing position, vertical and horizontal. Position swithing can

Description

Basic Info

| Model NO. | TQS-MZ1A |

| Structure | Horizontal Drilling Machine |

| Layout | Horizontal |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Warranty | 1 Year |

| Condition | New |

| After-sales Service | Remote Technical Support |

| Specification | 1200*900*1350mm |

| Trademark | TQS CNC |

| Origin | Foshan, China |

| HS Code | 84659900 |

| Production Capacity | 15 Sets / Month |

Product Description

TQS-MZ1A 1 Row Boring Machine

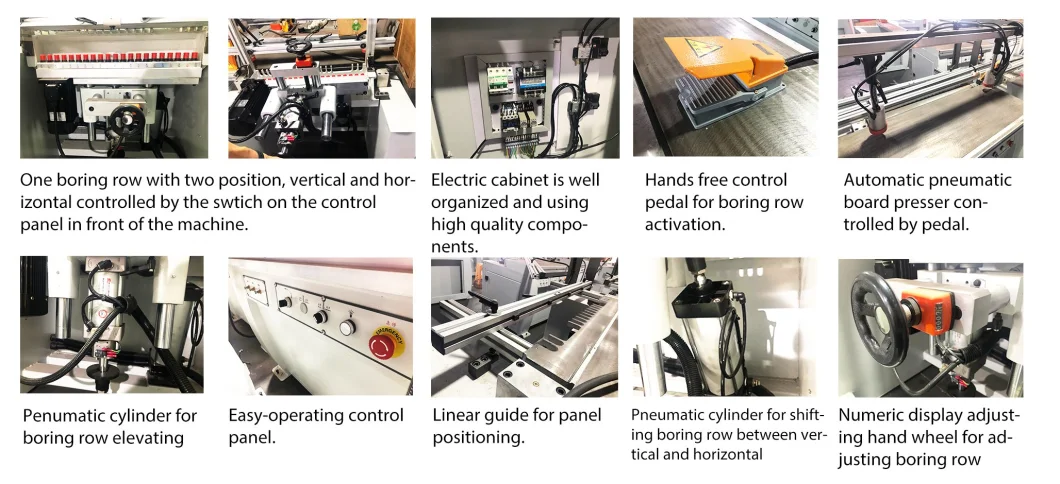

- One boring row with two standing position, vertical and horizontal.

- Position swithing can be activated by the knob on the control panel.

- automatic boring row elevating and board clamper actavating controlled by pedal.

Can be used for board drilling. Suitable for board with less drilling process.

| Model | TQS-MZ1A | ||

| Max. drilling dia | 35mm / 13mm | ||

| Max. drilling depth | 60mm | ||

| Total number of spindles | 21 | ||

| Installation dia. of drill bit shaft | 10mm | ||

| Spindle speed | 2840rpm | ||

| Total power | 1.5kw | ||

| Overall dimension | 1200*900*1350mm | ||

| Weight | 350kg | ||

| Compressed air pressure | 0.5-0.6Mpa | ||

FAQ:

1. What's your guarantee? Which type after sale service can you provide to us?

All the machine, we can offer the 1 year guarantee to our customers; any parts damaged due to the quality issue, we will send the parts via DHL, Fedex or air shipment urgently.

After sale service: if you purchased our CNC nesting center or edge bander, and we don't have any dealer or agent in your region, we will send our engineer to your site for installation and training ( you should pay the round-trip flight ticket, salary of engineer- each day 100.00USD, also take charge of the local accommodation. ). Considering the situation, we can do the online training. Also any small issues, you can knock us online, we will offer the rapid action to your concerns.

2. Which type payment term can you accept? How could we keep our capital safe?

We can accept the T/T and L/C at sight. We have more than 10 years exporting experience, so we know more about the capital safty concern of our customer. We will offer the video call or pictures to your side, during our loading, then you can check what we have done for the loading, if any cheating, then you can control your payment (T/T or L/C).

3. What is the leading time, if we did the payment to your side?

The leading time of most common machines, will be 10-25 days after collecting the down payment / copy of L/C. Specially designed production will take little bit longer time.

4. Can you accept some O.E. M service to us? or any other service could you do for us?

We have more 15 years experience in the woodworking machinery industry, also has more than 5 experienced engineers, so we can do the special design according to your requirement.

Also our exporting team has more than 10 years experience in this field, so they can help you to purchase relevant products, parts or tools, which can save your time and your cost.

Prev: Shenyang Symg Pbc 110 (f) M CNC Horizontal Boring Milling Machine

Next: Large Strong Horizontal Boring Machine TPX6111B TPX6111B/3

Our Contact

Send now