High Speed CNC Machining Center Fanuc System CNC Vertical Milling Machine Center Vmc1890

High Speed Cnc Machining Center FANUC System Cnc Vertical Milling Machine Center VMC1890 The whole structure is made of

Description

Basic Info

| Model NO. | VMC1890 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.009 |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, RoHS, ISO 9001 |

| Condition | New |

| Transport Package | Wooden Box Packing |

| Specification | 5000*3900*4000 |

| Trademark | Longkai |

| Origin | Suzhou, China |

| HS Code | 845710100 |

| Production Capacity | 200 Sets/Year |

Product Description

High Speed Cnc Machining Center FANUC System Cnc Vertical Milling Machine Center VMC1890

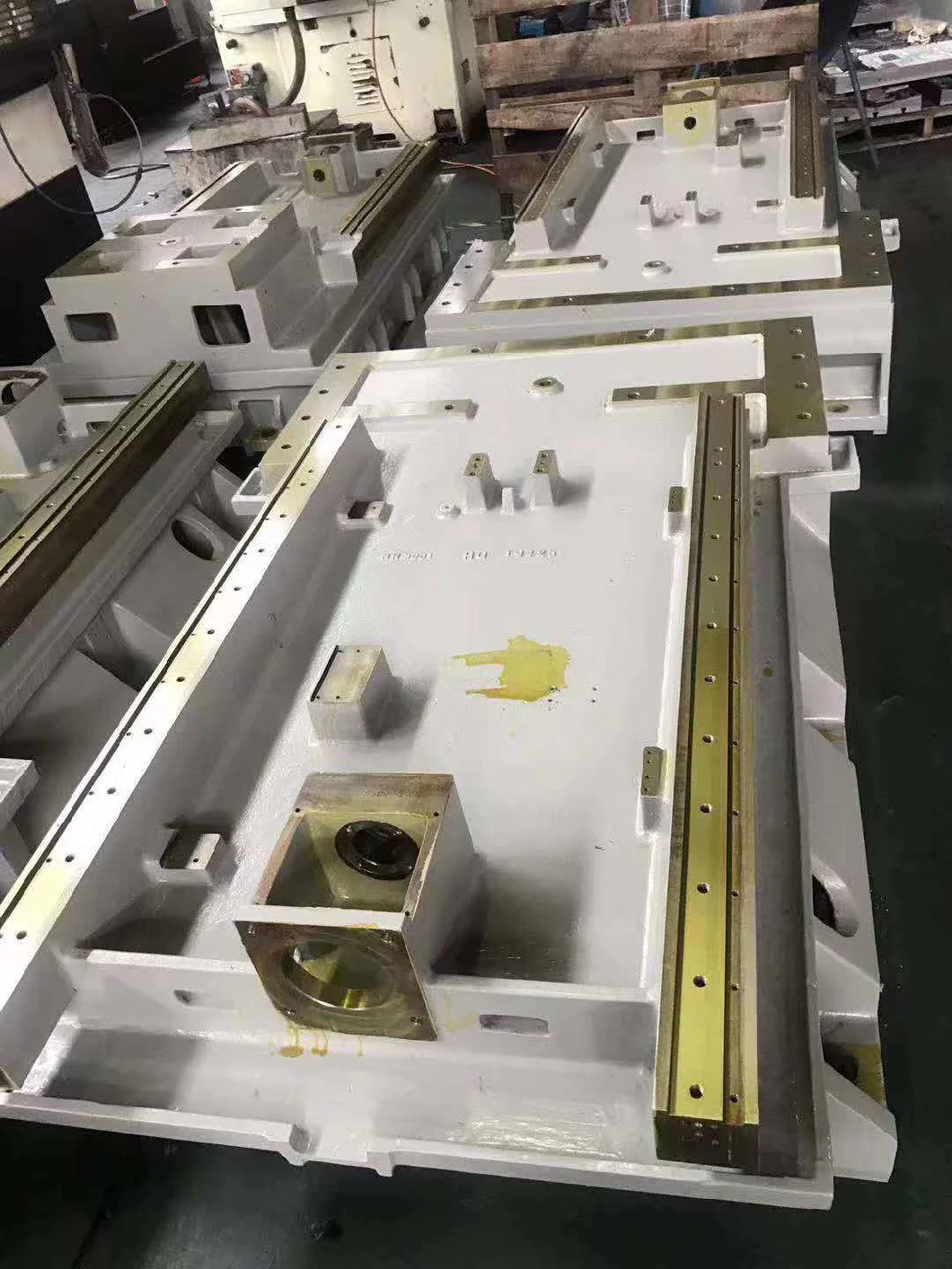

The whole structure is made of high toughness and high grade cast iron. After high efficiency annealing, the internal stress of the material can be effectively eliminated to ensure the best accuracy, stability and durability. The Y axis of the base is designed for the structure of the two-rail rail, the wire gauge is 850mm, and the support column of the track surface has good stability and rigidity, which is of good quality for the mold manufacturing of general processing. The counterweight system is equipped with the track of counterweight block, so that the spindle head can obtain support when it moves up and down, and can effectively buckle the machining problem caused by vibration, ensuring the accuracy is stable. Pillar to big "people" word design of large span, high rigidity and high stability, cooperate with Zhi solid stable base link, more show the accuracy and precision of processing, can achieve perfect requirements. The saddle and the table are double box design, which can reduce the vibration during processing, so as to ensure the processing accuracy.

High quality VMC1370 3/4/5 axis optional CNC vertical machining center

| Model | LK-1890 |

| X-axis Travel (mm) | 1800 |

| Y-axis Travel (mm) | 900 |

| Z-axis Travel (mm) | 700 |

| Three axis cutting feed | 1-1000 |

| Spindle speed (rpm) | 12000 |

| Spindle motor power (kw) | BIIP30/ 8000 |

| X axis motor power (kw) | BIIP30/ 2000 |

| Y axis motor power (kw) | BIIP40/ 2000 |

| Z axis motor power (kw) | BIIP40B/ 2000 |

| Table area (mm) | 900*2000 |

| X-axis rapid displacement (mm/min) | 30000 |

| Y-axis rapid displacement (mm/min) | 30000 |

| Z-axis rapid displacement (mm/min) | 30000 |

| Spindle center to column guide rail surface | 950 |

| Spindle taper | BT40 |

| quantity | 24 |

| Positioning Accuracy | 0.015 |

| Repetitive Positioning Accuracy | 0.012 |

| Spindle speed (belt) | 6000/8000 |

| Three axis fast moving feed | 20/20/15 |

| Bearing of worktable (kg) | 1800 |

| Machine total weight (kg) | 17000 |

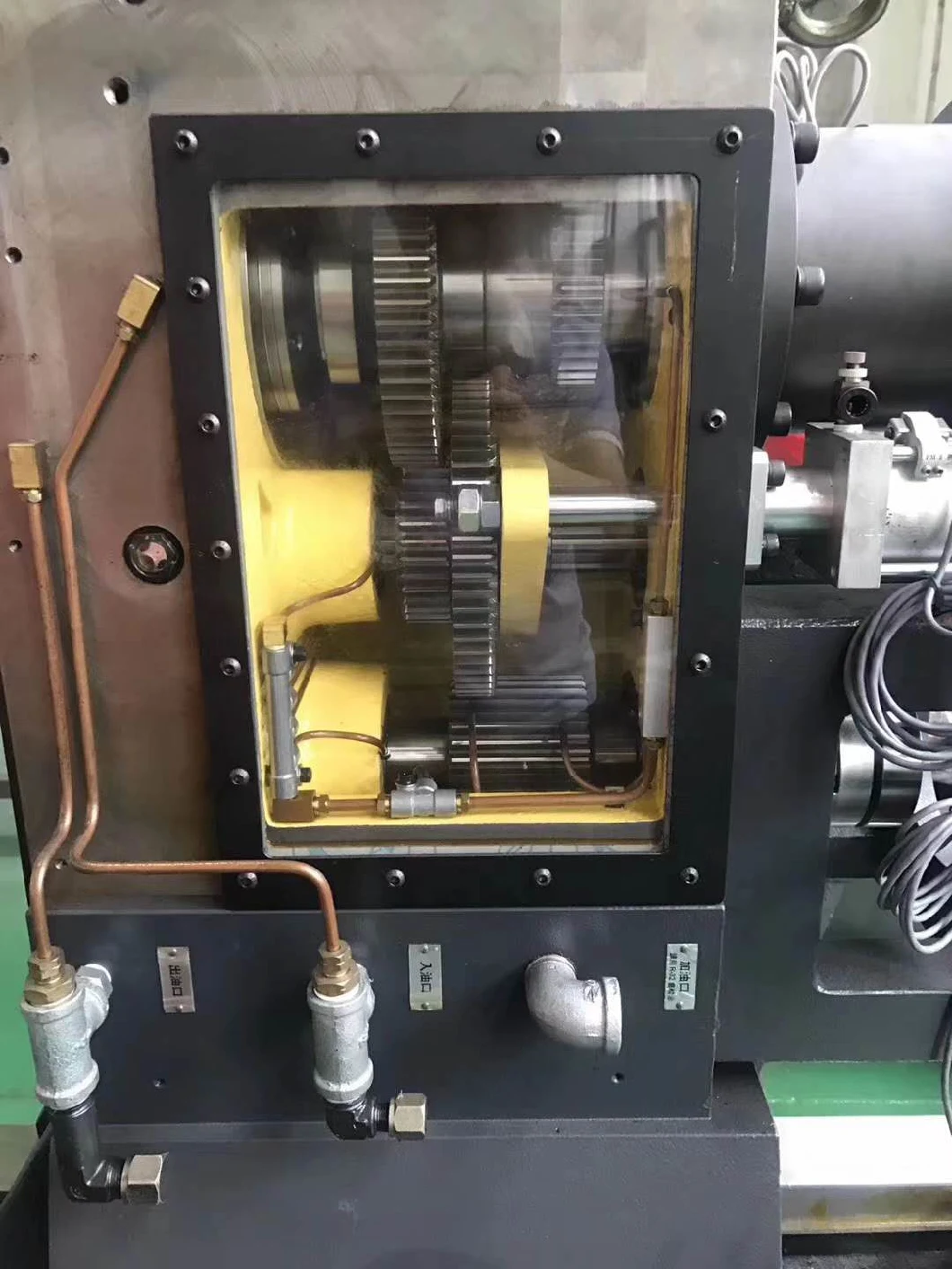

II. Structural performance of machine tool1. Fuselage designThe fuselage and saddle are reinforced by mountain shaped ribs, with the shortest force streamline, ensuring the best rigidity of the fuselage.Based on the excellent engineering design, the stiffeners of the base and column of the machining center can resist the torsion and damping, and transfer the cutting vibration to nonCutting area. The column is designed with torque tube, which can provide excellent rigidity, bending and torsion resistance Ultra wide base design,At the same time, lower the center of gravity of the base and adjust the center of gravity of the machine tool to the best stable height. The span at the bottom of the column is widened to improve the stability of the machine tool.2. spindle headThe contact length ratio between the main shaft and the column is appropriate to provide stable support for the main shaft. Independent cooling system is built in the spindle head to stabilize the spindle continuouslyThe head heat is in a reasonable range, which reduces the thermal extension of the spindle and ensures the machining accuracy.3. counterweightIn response to the processing requirements of different models, the following counterweight methods are adopted:Counterweight: low failure rate and long service life;Nitrogen counterweight: rapid action, no noise, greatly improved processing accuracy, increased machine life;No counterweight: in order to meet the requirements of high speed and high sensitivity processing, the machine tool adopts the method of no counterweight, and enhances the requirements of servo motor and screw,Z-axis with brake, to ensure the accuracy of the machine tool is stable and lasting, and increase the service life.4. screw rodIt adopts imported grinding level pre drawn double nut screw rod to eliminate reverse clearance. After heat treatment, it has high rigidity, wear resistance, torsion resistance and long service life, which guarantees high machining accuracy of the machine.5. AC servo motorAdopt original imported from Japan, super high performance servo motor, provide stronger power when heavy cutting.In the case of low feed, high torque can still be maintained.Higher than 10000 (pixel) resolution and closed-loop position feedback ensure high accuracy.High quality coupling ensures that the screw rod moves with the axis of the motor.6. Lubrication systemThe whole machine adopts a positive displacement lubrication system and a de pressurized oil pump, with stable pressure and flow, which effectively transports the oil to each lubrication point and provides uniform forced lubrication for each slide surface, so as to ensure the accuracy and service life of the machine tool. Chip remover systemIII. functions of CNC systemCNC system is Mitsubishi or FANUC system. Equipped with RS232C interface, with data transmission function.Three axis simultaneous movementMinimum instruction unit: 0.001mmFast displacement speed adjustmentFeed rate adjustmentSuspendAutomatic origin reset G28Second origin reset G30Hand artery wave generatorWorkpiece coordinate system G54-G59Drilling fixed cycle G73, G76, g81-g89 / g80Rigid tapping g84, G74Air runEmergency stopMDI functionSelective single node skipSingle section implementationProgram suspensionManual control function: manual rapid feed, inching feed, hand wheel feedTool length correction G43, g44 / G49Tool radius correction G41, G42 / G40Memory compensation of pitch errorBack gap correctionArc interpolationLinear interpolationScrew interpolationSearch for program number and serial numberSub process callConversion of public and British systemTransmission interface, DNC capacityDifferent alarm displayLadder diagram displayMacro programs and variablesMirror functionSimple program graphic display functionNC control language: Chinese, English, Japanese and other five languages are optionalMonitoring function: full coordinate display, spindle speed display, spindle load display, PLC ladder circuit monitoringProtection function: over travel protection, overload protection, interlock function.IV. attached dataAccuracy inspection tableA set of instructions for Mitsubishi or FANUCA set of Chinese operation instructionsV. installation and commissioning1. Please install the three-phase 380V power supply, 50Hz power unit and suggest to attach the voltage regulator.2. After the equipment arrives at the factory, open the box together with our representative for inspection. If any damage or shortage is found, please inform our company immediately.3. After the arrival of the goods, your company shall first carry out mechanical positioning, horizontal rough adjustment and other work, and then the supplier shall install fine adjustment and training, and your company shall inform our company to send personnel at least 7 days in advance.4. Please assist our installation and commissioning personnel to arrange accommodation, meals and transportation,5. Please designate the operator and maintenance personnel of the machine, and assign special personnel to assist in the installation and commissioning of the machine.6. After the acceptance of the whole machine, your company shall sign the acceptance certificate of installation and debugging in real time, in duplicate, one for each party.

Our main products :* Servo Mid-speed WEDM machine* Stepper medium speed wire cutting machine* High efficiency fast Wire cutting* CNC drilling machine* Drilling EDM* EDM molding machina* Grinding machine* Turret milling machine* CNC drilling and milling machine* CNC engraving and milling machine* Vertical machining centerAll the above products have passed CE, SGS certificates.Our Strength:* Over 12 years manufacturing experience in CNC lathe machine.* The company abides by the concept of "providing high-quality,stable and cost-effective products and good services to the clients by relying on advanced and reliable technology, * Always adheres to a large amount of research and development investment and continuous engineering improvement* Longkai EDM machines are with high cutting accuracy, high cutting speed, high surface finish and high stability. * We have always been in the leading position of the reciprocating wire cutting machine, electrical processing power and control technology.After-sale Services:Warranty is one year.We would offer the parts (quality problem) free of charge during this period, freight collect.

Prev: Lathe/Built-in Lathe Center Frame 5-72mm Clamping Range

Next: Bymc Vmc1160 CNC Machining Center High Precision 3/4/5-Axis Vmc

Our Contact

Send now