CNC 3axis Vmc-V85 Vertical Machining Center CNC Vertical Milling Machine

Description

Basic Info

| Model NO. | VMC-V85 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.006mm/M |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Table Size | 900*450(1000*500*)mm |

| Machining | Parts Machining |

| Rotation Speed | Belt 10000/Direct Connect12000*-15000*Rpm |

| Spindle Taper | Bt40 |

| X Axis Travel | 800mm |

| Y Axis Travel | 500mm |

| Z Axis Travel | 500mm |

| Distance Between Spindle and Work Table | 170-670mm |

| Spindle Power | 7.5kw |

| Spindle Type | Belt or Direct Spindle |

| Three Axis Type | Linear Guide Way |

| Max Table Load | 500kgs |

| T Slot | 3-18*130/5-18*102 |

| Dimension | 2050*2535*2660 |

| Gross Weight | 4200kg |

| Transport Package | Wooden Package |

| Specification | 2450*2535*2660mm |

| Trademark | JOINT |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 150 Sets |

Product Description

Introduction:

This V series CNC machine center has the characteristics of fast feed speed and high rotation speed, so it is suitable for batch parts with many tools, complicated processing and multiple processes. Mainly processing cabinets, complex curved surfaces, heterosexual parts, disks, sleeves, plate parts, etc., are widely used in electronics, machinery and automotive, automation, medical, national defense and other fields.

Product Characteristics:

High Quality CNC Machining Center CNC Milling Machine with German Technology VMC-V851. V-series machines are designed for high efficiency parts processing. Three axis adopt ball linear guide way or roller linear guide way, rapid feed:48m/min2. The unique large-span structure of the base and column can withstand the inertia caused by high G with high overall dynamic response.3. The direct-connected short nose high-speed spindle can improve efficiency, reduce tool wear and maximize the transmission efficiency of the spindle motor. Improving processing accuracy and extending spindle life.4. Equipped the rear chip conveyor with a large flow chip removal system, which can meet the requirements of rapid chip removal..

Why we design VMC-V85:

First of all, 850 two axes linear guideway model is the traditional one, with thick fuselage, and relatively small screw pitch, and relatively slow processing speed, generally 24m/min. 850 series is used for processing aluminum workpiece, steel workpiece and mold, with characteristic s of high rigidity but low efficiency.

Second, v85 three axes linear guide way model is popular series for processing aluminiun workpiece in recent years because of light and handy fuselage and high three axes moving speed, generally 48m/min. But when it process steel workpiece, it's rigidity is not enough, and its speed need to slow down.However, now lots of customers receives include aluminium and steel, and usually it is batch orders. such as the automation module processing industry

For these customers, buying one of these two models is not enough for them. 850L is not high efficiency for aluminium parts and v85 is not rigid enough steel parts. And it is not high cost performance for buying both of them. So we launch a new model v85 which can meet customers'efficiency and rigidity requirements. And it's cost hasn't increased much.

New Comer Advantages:

1. First, rigidity is greatly enhanced. Some V855, V856 models on the market, that is, the rigidity is increased, just widened the base, the rigidity is improved, but not very much, because from the force analysis, the biggest force is the spindle box and column, and finally to conduct to the end seat. So our V855 is according to the force analysis and improvement of the structure of the spindle box on the fuselage widened, and the pillar is shortened, pillar line rail mounting surface widening, Z axis increased to 6 sliders, column on both sides of the widening, increase the knife library brackets, on both sides of the balance, it is adopted the design of high precision mould machine V85P, base also widened, The rigidity of the machine was increased across the board. The structure of V855 can withstand the inertia generated by accelerated processing speed, in the machine tool fast feed, the overall dynamic response characteristics are higher, compared to THE V85 model, the cutting speed can be accelerated, the cutting effect will be better, but also can easily process steel parts. Now we use A ф 16 milling cutter, processing 45 steel, feed speed 3500, speed 4000, depth 50 wire, machine tool without vibration, very smooth, there is no vibration sound. Let's see the processing effect, knife lines is neat, smooth and bright.2. In cooperation with Fanuc, we have developed an independent single page to display the alarm and maintenance functions of oil pumps and refueling machine tools. You can operate on one page by clicking directly without switching to different pages, which speeds up the operation efficiency of users.

3. There are 10 grade parameters in the system. Users can choose different grades according to their own processing requirements to get different processing effects. For example, rough machining, choosing level 10, can reach high processing efficiency. When you just need low finishing, you can choose level 5, processing speed will become slower for high finishing processing. We also set up a professional packet storage module for this machine additionally. If customers have special and regular processing requirements, its adjusted parameterss can be stored in the module, then at next time customers can directly use this module when processing similar parts, no need to adjust again. This storage module is our unique technology. Similar products currently on the market do not have this technology in China.

Specification:

| Model | VMC-V85 | |||

| Travel | X axis travel | mm | 800 | |

| Y axis travel | mm | 500 | ||

| Z axis travel | mm | 500 | ||

| Distance between spindle and table | mm | 170-670 | ||

| Distance between spindle and column | mm | 524 | ||

| Table | Size | mm | 900*450(1000*500) | |

| Load | kg | 500 | ||

| T slot size | mm | 3-18*130/5-18*102* | ||

| Spindle | Taper | BT40 | ||

| Installment diameter | mm | Φ140 | ||

| Rotation speed | r/min | Belt 10000/Direct 12000*/15000* | ||

| Three axis | X axis rapid feed | m/min | 48 | |

| Y axis rapid feed | m/min | 48 | ||

| Z axis rapid feed | m/min | 48 | ||

| Cutting feed | m/min | 15 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.006/0.006/0.006 | |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.005/0.005/0.005 | ||

| Other | Dimension | mm | 2450*2535*2660 | |

| Weight | kg | 4300 | ||

Applicant Industry:

| Standard accessories: 1. Mitsubishi/ Fanuc controller system with AICC2 Function V85C direction connectin with 12000rpm SPEEDCN spindle 2. Fully enclosed cover3. Pneumatic system4. Anto lubrication system5. Work piece coolant system6. Heat exchange7. Air gun8. Water gun9. Spindle oil coolant10. 24T Arm type tool magazine11. Rear flishing12. Hand wheel13. RS232 Interface14. Alarming light15. Working light16. Guide way cover17. Technical documents18. Operation manual | Optional accessories: 1. Screw type conveyor2. Chain type conveyor3. 4 axis Rotary table4. Coolant through spindle (CTS)5. Spindle rotation speed can be direct connection with 12000rpm. |

Package:

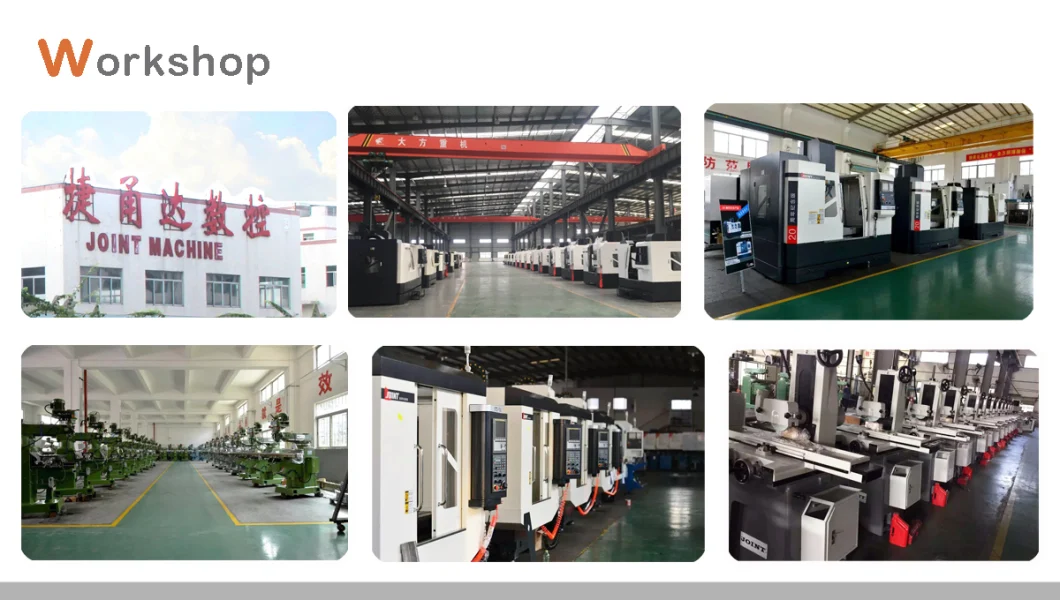

Shenzhen Joint Technology CO.,LTD., was established in 1995. One of our headquarters is located in PingHu town, Shenzhen City ,Guangdong province ,China, we are dedicating to research and development, production, sale, and service of mold processing machine tools and specialized machine tool equipments for machine work of excellent quality for more than two decades. There are eight series of products-high speed turret milling machine, precision surface grinding machine, EDM machine tool, CNC milling machine, NC milling machine, Gantry type machine center, CNC engraving machine, and CNC lathe machineOur own brand "JOINT " Has been the top quality machine's signal in domestic sales, JOINT also has been recognized as " GUANGDONG Famous Brand ", and milling machine was recognized as " TOP 10 Famous Brand of Milling machine " in China. Our product had been exporting to Europe, South America, Southeast Asia, the middle east etc, and enjoyed a good reputation there, Welcome your visit !

Prev: Lathe/Built-in Lathe Center Frame 97-515mm Clamping Range 6800 daN

Next: CNC Vertical Machining Center Vmc500 Vmc650 Vmc740 Vmc800 Vmc1050 Vmc1160

Our Contact