20m/Min Speed Dual-Spindle Dual-Turret CNC Lathe with Hydraulic System

Description

Basic Info

| Model NO. | DS-5246DTS |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.005 mm |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Max. Length of Workpiece | 240mm |

| Turning Diameter | Single Workpiece up to 200mm |

| Spindle Nose Taper | A2-6/A2-5 |

| Speed | 6000 Rpm |

| Spindle Motor Power | Main 11kw/Sub-Spindle 11kw |

| Collet Type | Hydraulic Collet |

| X1-Axis / Z1-Axis | 260mm/450mm |

| X2-Axis / Z2-Axis | 260mm/450mm |

| Controller | Fanuc |

| Z/X Axis | up to 25m/Min |

| Power Turret | Bmt55 12-Stations |

| Outer Diameter of Cutting Tool Shank | 20mm*20mm |

| Total Power | 35kw |

| Voltage | 380VAC 50Hz |

| Weight | 5300 Kg |

| Transport Package | Polyethylene Foam and Wooden Carton Box If Require |

| Specification | 2700mm*2500mm*2100mm |

| Origin | China |

| HS Code | 8458110090 |

| Production Capacity | 50000pieces/Year |

Product Description

20m/min speed Dual-spindle Dual-turret CNC Lathe with Hydraulic System

| CAPACITY | |

| Swing Over Cross Bed | Φ360mm |

| Swing Over Carriage | Φ200mm |

| Max. Length of Workpiece | 240mm |

| Turning Diameter | Bar Material up to φ52mmSingle Workpiece up to φ200mm |

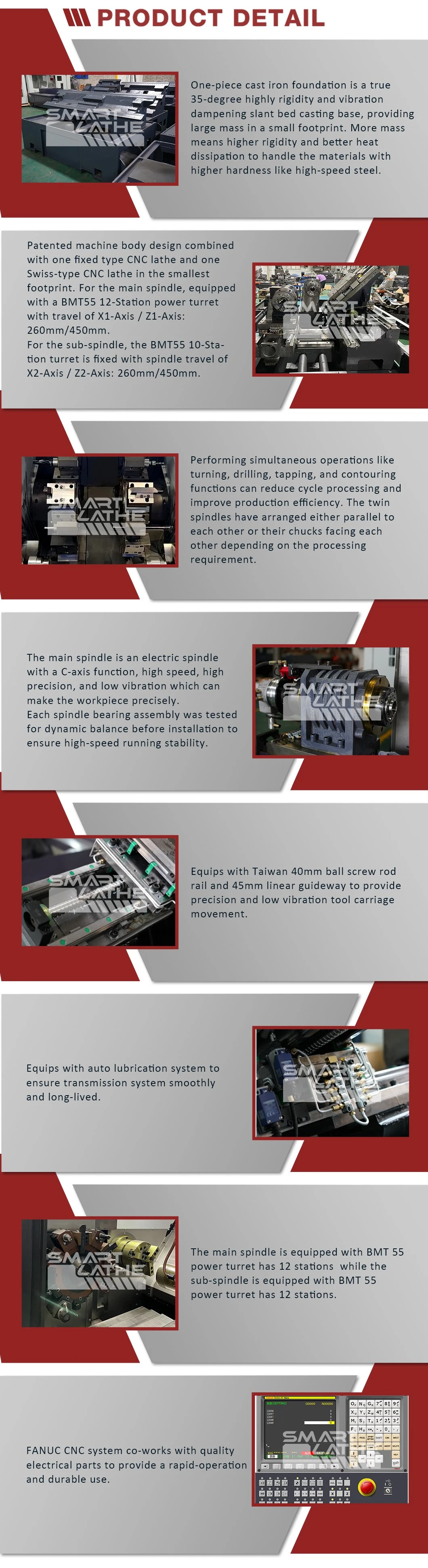

| Bed Type | True One-Piece Cast Iron |

| SPINDLE | |

| Spindle Nose Taper | A2-6/A2-5 |

| Speed | 6000 RPM |

| Spindle Motor Power | Main 11KW/Sub-Spindle 11KW |

| Collet Type | Hydraulic Collet |

| TRAVELS | |

| X1-Axis / Z1-Axis | 260mm/450mm |

| X2-Axis / Z2-Axis | 260mm/450mm |

| Guideway Type | 40mm TAIWAN Ball Screw RodX1-Axis/X2-Axis 45mm TAIWAN Linear GuidewayZ1-Axis/Z2-Axis 45mm TAIWAN Linear Guideway |

| Z/X Axis | Up to 25m/min |

| Machining Accuracy | ±0.005mm |

| Surface Roughness | Ra 1.6 |

| TOOLS | |

| Power Turret | Turret #1: BMT55 12-Station Turret #2: BMT55 12-Station |

| Outer Diameter of Cutting Tool Shank | 20mm*20mm |

| CNC CONTROL | |

| Controller | FANUC |

| POWER SUPPLY | |

| Total Power | 35KW |

| Voltage | 380VAC 50Hz |

| DIMENSIONS | |

| Dimensions (L/W/H) | 2700mm*2500mm*2100 mm |

| Weight | 5300 kg |

Standard Configuration

| Fully Enclosed Splash Guard with Top Roof | 11KW/11KW Spindle Servo Motor | Telescopic Guards for X/Z axes |

| Spindle Speed 6000 RPM, A2-6/A2-5(Sub-spindle) | Automatic Lubrication System | Coolant System |

| Lubrication System | Hydraulic System | Coolant Tank |

| Oil Separator | LED Working Lamp | Electronic Handwheel (MPG) |

| Coolant Gun | Toolbox and User Manuals | Power Turret(#1:12-station#2: 12-station) |

| Collet (2 Sets) | C axis | CNC Simulation |

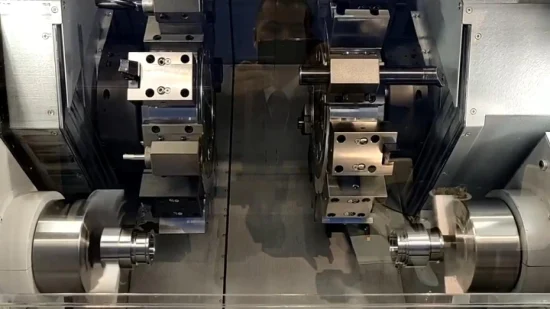

DS-5246DS is a professional and high-end model with a dual spindle and dual turret turning centers specialized in the multi-task process for precision complex parts in one setup, which could compete to handle the turning process of double-ended parts in a single setup with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bar material up to φ52mm or single workpieces up to φ200mm. This model allows you to increase maximum productivity by streamlining the process.

Features

With dual everything, DS-5246DTS gives you flexibility that is only limited by your imagination. The turning centers are outfitted with up to 28 horsepower right and left spindles capable of 6,000 r/min rotation.Their BMT 55 12-station turret plus BMT 55 12-station sub-turret, and 24-position turrets give you 48 tools to work with, not to mention live tooling on both turrets for full milling capabilities. This design provides the operator with maximum flexibility when setting up complex jobs or when redundant tools are required for tool life management.

Company Profile

1:How can I choose machines?

A: for the model selection, please send us the drawing of the turning part and our engineer will evaluate it and provide the suitable configuration of the CNC lathe fit for your needs.2: What's the main products of your company?

A: SmartLathe concentrated all its resources to develop successfully the SL series of the CNC slant bed lathes including the SL-07, SL-25, SL-36, SL-46, and the CNC Turning-Milling machines to help our customers in the field of prototyping, entry-level business, and the craftsman with a bootstrap budget.3: Where is our factory located? How can I visit there?

A: Our factory is located in Foshan City, Guangdong Province, 528300 China. You are warmly welcome to visit our factory.4: What are the Trade & Payment Terms?

A: FOB, CFR, and CIF are all acceptable. T/T,30% initial payment when order,70% balance payment before shipment; Irrevocable LC at sight.5: What's the MOQ?

A: 1 set. We will offer you're a better price if you order more.6. What is the delivery time?

A: The full series of standard models are in stock. For a customized one, it depends.7. Do you have any certificates?

A: Yes, our machine is CE-compliant, and our factory is ISO 9001 accredited.8. What is the warranty period?

A: The warranty period is generally 13 months after B/L date.9. Machine installationA: SmartLathe could assign the technician to the place for the on-site installation if requested by the purchaser.10. Technical SupportA: The technical response is available within 12 hours while the solution for the troubleshooting is provided within 48 hours.

Prev: Sponge Foam Mattress Machine Cutting Horizontal Boring Foam Sponge Machine

Next: 8 inch New Z-MaT Seaworthy Package dual spindle turret lathe

Our Contact